A proven technology with global acceptance.

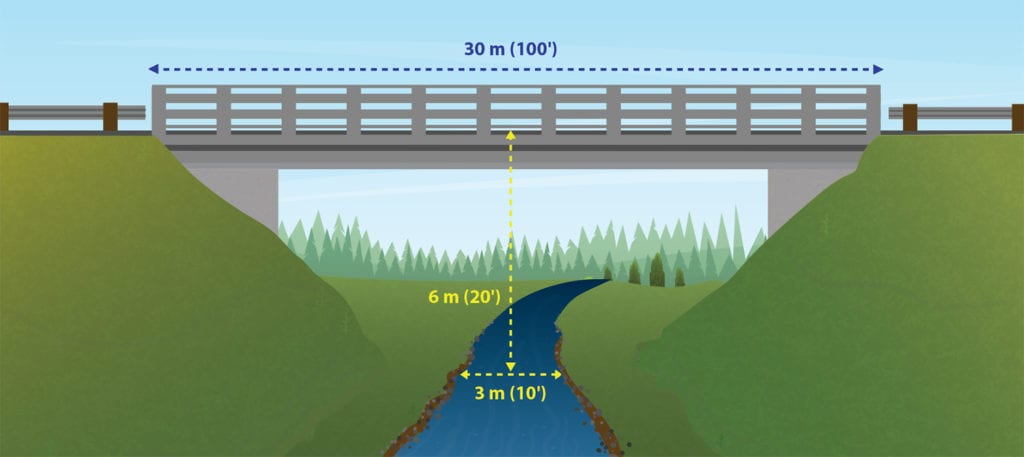

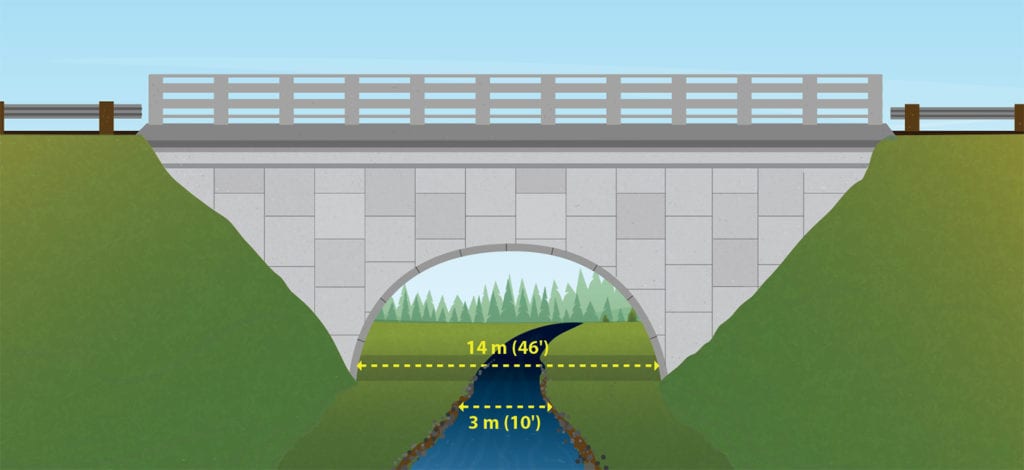

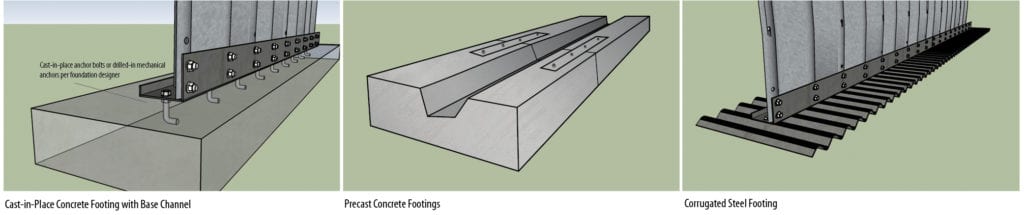

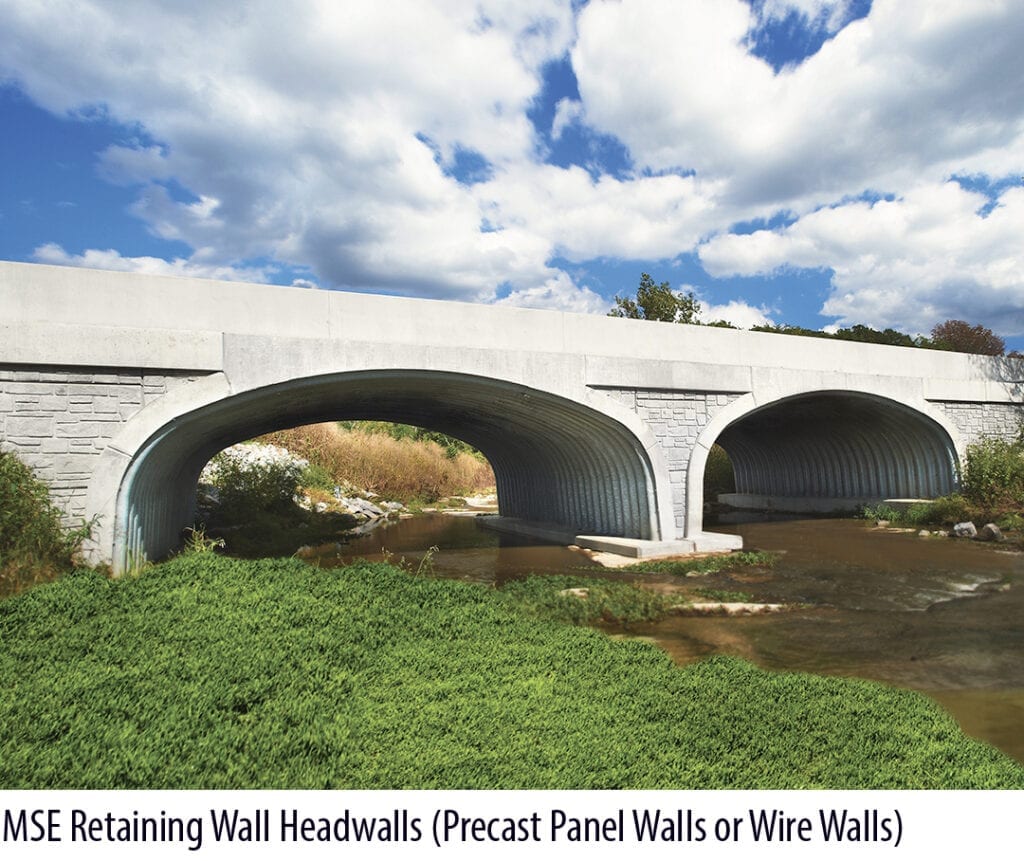

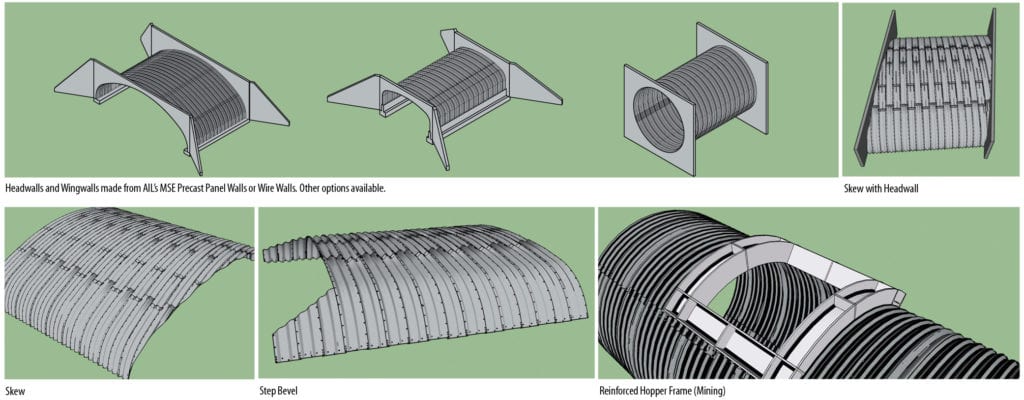

With many thousands of installations worldwide over the last 60 years, Buried Metal Bridge design and analysis continues to evolve, as their behaviour is better understood. Collaborative efforts by many academics at prominent research facilities lead the way through advanced finite element modeling initiatives, which are validated by rigorous field and laboratory testing programs.

Since AIL first introduced our deep-corrugated structural plate solutions over 30 years ago, there has been growing global acceptance of this technology. Numerous countries have adapted their national bridge code standards and specifications to recognize and support large span Buried Metal Bridge design.

Canada

CSA S6:19, Canadian Highway Bridge Design Code, Section 7, Buried Structures CSA G-401, Corrugated Steel Pipe Products

USA

AASHTO LRFD Bridge Design Specifications, Ninth Edition, 2020 ASTM A761/A761M, A796/A796M

Australia and New Zealand

AS/NZS 2041.1, 2041.2, 2041.6

Sweden

TRITA-BKN Report 112, Design of Soil Steel Composite Bridges