October 20, 2020

Our recent Bolt-A-Plate reline of a failing culvert in Caledon, a town in the Regional Municipality of Peel in the Greater Toronto Area, has provided impressive benefits over the full replacement option:

- Huge savings on time, labour and installation

- No road closure or traffic interruption hassles

- A +75-year design service life with Polymer Coating

This project was a great example of several stakeholder teams — owner, consultants, suppliers, contractors —overcoming challenges posed by the COVID-19 pandemic and working well together to deliver a successful result.

We worked together with the contractors to meet a very tight delivery schedule, as it had to be completed within a fishery window set by the Toronto Conservation Authority. Internally, we had to shift other projects with our engineering and fabrication teams to expedite the delivery and, in the end, we over-delivered on the promised delivery time.

Slip line culvert relining is an “advanced” trenchless construction process

The tight site offered very little room at one end of the culvert and no access at all at the other end — but this was not a problem for the slip line construction process where the new culvert is built in stages and advanced along on rails into the old structure. Once this process is completed, the annulus is filled with a low-density, non-shrinking cementitious grout.

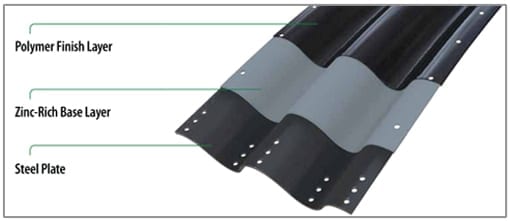

Best•Kote Polymer Coating: +75 years of performance

AIL’s Best-Kote Polymer Coating can be used on all or part of our structures to maximize protection against specific corrosive threats posed by the aggressive water chemistry of the site.

This two-layer coating system is factory-applied to the finished plates through an electrostatic-bonding process that ensures 360° protection. The first layer is a zinc-rich base layer for excellent corrosion resistance and barrier protection. The second layer is a polymer finish that provides superior resistance to corrosion, abrasion and inorganic acid, salts or alkali (diluted).