November 7, 2022

The client group on this project (Calgary Airport Authority, Travel Alberta and the City of Calgary) asked us to propose a unique and original aesthetic treatment for the MSE Precast Panel walls supporting the Barlow Trail Interchange at the airport. We immediately collaborated with our precast partner, and they proposed an innovative technology that applies a halftone dotted image to the concrete surface.

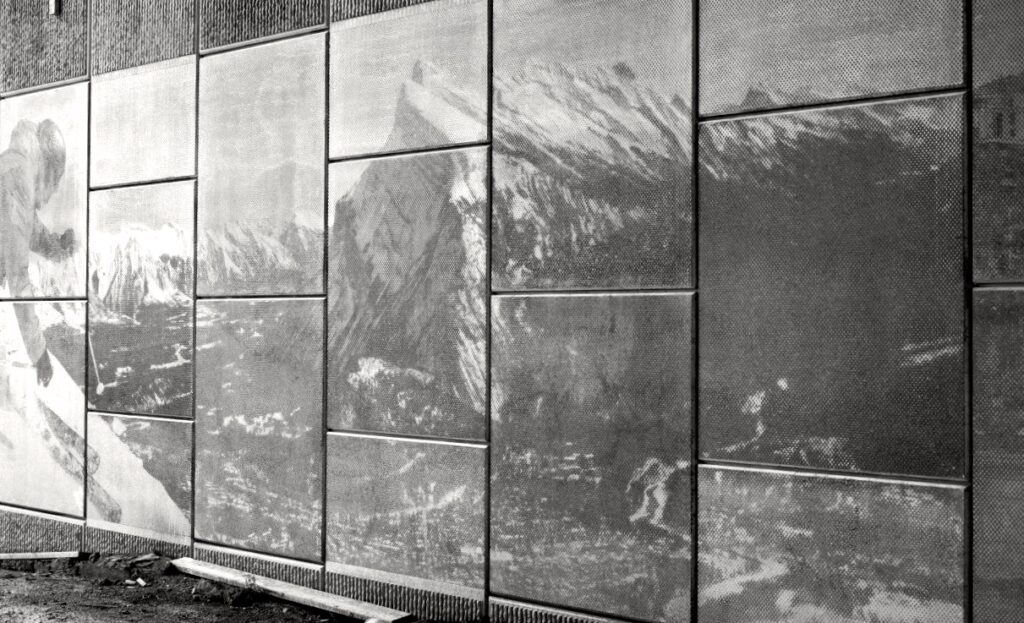

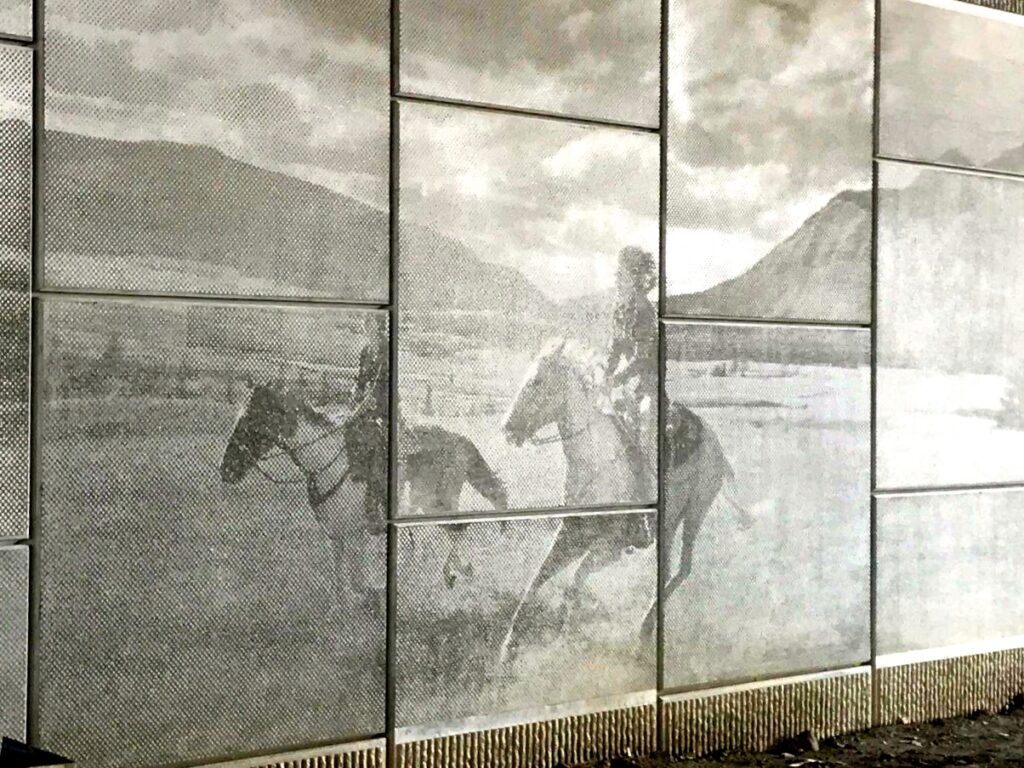

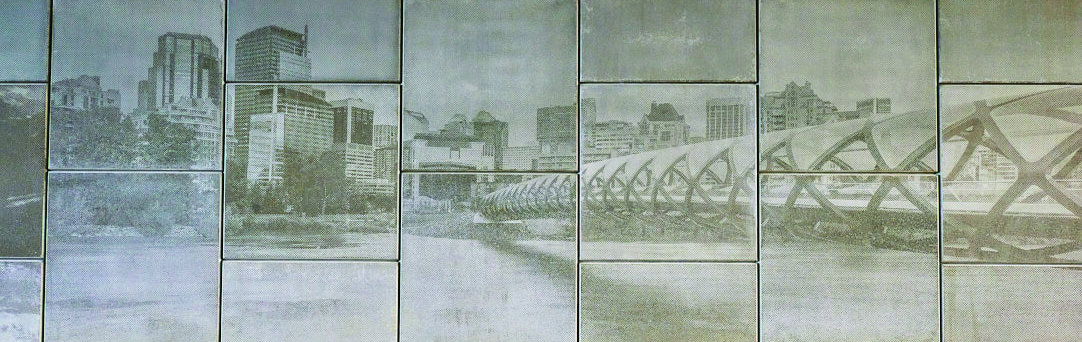

The resulting mural walls highlight many of the attractions, natural features and cultural icons of Calgary and the surrounding area in continuous montages.

Mural walls used ground-breaking “sugar sheet” casting technique

The project utilized a plastic foil casting technique with unique casting forms for each panel that combine to present a continuous picture when installed. The panel image artwork required additional customization to ensure the panels lined up properly and extra care was taken with the location of the panel gaps versus the image detail. We also used a special concrete mixture for a better contrast to accentuate the design.

The panels were photographed and clearly labelled prior to shipping so on-site handling could be kept to a minimum. Extra care was also taken in the shipping of the panels with a “Toaster Design” pallet protection system that effectively wrapped each panel.

The wall was scheduled to be installed over the winter, so we took the initiative to use a winter backfill material in the design of the wall.

Value engineering: global stability reduction from tender to design

Preliminary design work showed significant differences between the engineered backfill required by the external design done at the tender (the Geotechnical Engineer’s scope) and that required by AIL’s internal MSE wall design/scope. To reduce the cost to the contractor and the owner, we provided additional design details to the Geotechnical Engineer to rerun their analysis and optimize their design. This exercise successfully lowered the construction cost by reducing the extent of the reinforced zone; one wall showed reductions up to 5m in length and the total engineered backfill volume was reduced by 8%.

This type of detailed MSE mural wall really requires a one-team approach and a strong relationship with both our pre-casters and the carriers. AIL stayed pro-active during the life cycle of this project — from purchasing additional liners to ensuring adequate resources were available to meet the timeline. This included constant communication with all stakeholders from design, production and delivery.

Our Technical Sales Representative took a final walk-through with representatives from the client group, and all agreed that the final effect is quite striking and makes a great visual statement to travellers using the airport.