The interchange at Sarcee Trail and the TransCanada Highway (16th Avenue NW) helped support Calgary’s traffic demands and provided access to the newly developed Trinity Hills — a large residential community of luxury apartments, modern townhomes, seniors’ housing and supporting commercial developments next to Canada Olympic Park on the western side of the City.

Take a 360° drone video tour of this project >>

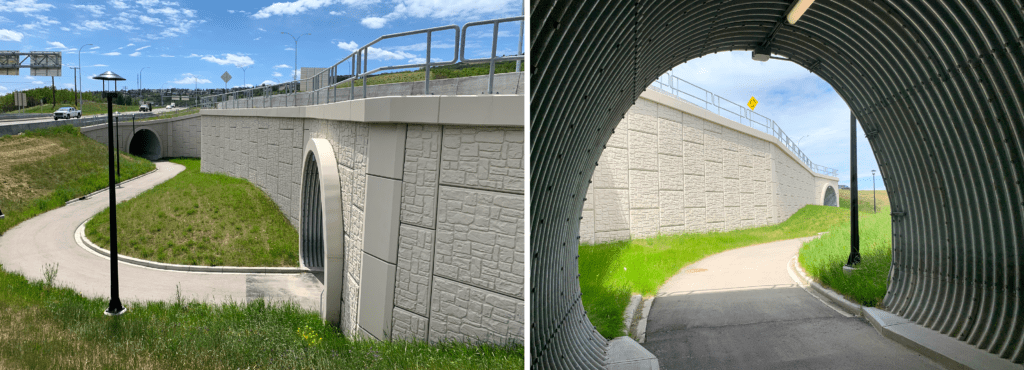

Tunnels connect neighbourhood active transportation network

Key to the development’s success was having interchange access to Sarcee Trail. The developers also needed connectivity to the City’s active transportation trail network.

AIL designed and supplied two Bolt-A-Plate pedestrian tunnels and MSE Precast Panels Walls for the project. Under a progressive design-assist model, Urban Systems and RJC Engineers worked with the developer, the City and Graham Construction to develop designs optimized for durability, economy and constructability. AIL has partnered on many projects with the City and Graham over the years.

The Sarcee Interchange is very close to the Bowfort Interchange, another large-scale project featuring custom MSE Precast Panel Walls designed and supplied by AIL.

Active transportation networks part of a more sustainable Calgary

Creating neighbourhood active transportation networks is a vital part of many progressive urban infrastructure plans. It prioritizes people on foot or bike, and connects them with local destinations conveniently, safely and enjoyably. Learn more about Sustainable Calgary’s Neighbourhood Active Transportation Networks Policy.

AIL’s Buried Metal Bridges are the more sustainable choice

When planning sustainable infrastructure projects, it is important to look at the full picture of the materials used, how they are made and transported, their life-cycle maintenance and what happens to them at end of their lifespan.

AIL’s Buried Metal Bridges and Tunnels have a substantially lower life cycle carbon footprint than concrete bridges or structures. This is due to several factors:

- Steel is the world’s most recycled material*

- Less energy is used in the production and shipping of Buried Steel Bridges than concrete bridges

- Buried Steel Bridges can be built in significantly less time, reducing disruption time and detours and expediting construction schedules

- Buried Steel Bridges require less maintenance than concrete beam bridges

- Zinc used in galvanizing is a naturally occurring material and is 100% recyclable**

Plus, there are many more compelling reasons to choose Buried Metal Bridges and Tunnels instead of concrete. Take a look at our Buried Metal Bridge Benefits webpage to learn more.

*Reference: www.aisc.org

**Reference: https://galvanizeit.org/hot-dip-galvanizing/is-galvanizing-sustainable/hdg-environmental-advantages