GRS technology puts the dirt to work in buried arch bridge solutions.

AIL’s GRS technology is a patented buried arch bridge system originally developed for the forestry and resource industry sectors. It uses steel anchor rods to connect a Super-Cor structural steel plate arch to the backfill/geotextile composite and transfers the loads into the surrounding GRS mass.

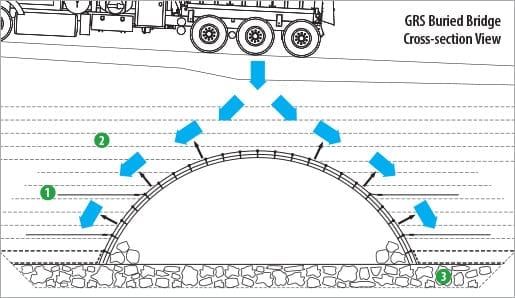

How GRS buried arch bridge technology works

GRS corrugated metal bridges are a soil-steel-bridge geotextile composite structure. The bridge’s dead and live loads are supported by the reinforced soil, structure and natural or improved subgrade soils.

1. Anchor Rods – The soil arch structure is connected to the GRS soil mass composite with soil anchor rods. The anchor rods ensure the soil bridge structure maintains shape during backfilling.

2. GRS – Closely spaced geotextile between layers of compacted backfill act to confine the soil particles.

3. Boulder layer foundation – Used in lieu of conventional strip footings or pile foundations.

Fish- and wildlife-friendly corrugated steel bridges

GRS buried arch bridges maintain the original streambed, thus reducing the impact on fish and wildlife. Where the streambed does not exist, streambed reconstruction is part of the soil-steel bridge design. Corrugated metal bridge structures can be sized wider than the natural streambed to permit passage of other wildlife. Flexible headwall designs help to minimize the footprint of the soil arch bridge.

Rapid buried arch bridge installation

AIL’s GRS corrugated steel bridges are excellent alternatives to beam bridges, truss bridges or concrete culverts. Their prepared boulder foundations eliminate the need for concrete footings and, in many cases, pile foundations. The corrugated metal and other components ship on a single truck to be installed with conventional road-building equipment and local labour in only a matter of days. Boulder foundations and backfill materials are typically sourced locally, reducing hauling costs and accelerating bridge construction in regions with limited infrastructure.

Recommended for remote bridge construction applications

AIL’s GRS solutions make very efficient soil arch bridge solutions for resource-road crossings, stream crossings and fish passages in remote locations and environmentally sensitive areas.

AIL Geotextiles are also available for your GRS projects

We offer three increasing strengths of AIL High-Performance Woven Geotextiles that are recommended for GRS projects: AIL90, AIL100 and AIL120. Learn more about our complete line of Geotextile and Silt Fence products and download Technical Data Sheets here, or talk to one of our GRS experts at: 1-877-245-7473.

Discover the many benefits of buried arch bridges

Structural Plate Bridges or Buried Metal Bridges offer many advantages over concrete equivalents and traditional site-built beam bridges.

Visit our Buried Bridge Benefits page to learn more >>

Bring enhanced aesthetics to your buried arch bridges

From interior finishes and lighting to exterior end treatments and even urban greenways on top, take a look at the full range of possibilities in our Design Ideas Gallery.

Visit our Design Ideas Gallery to learn more >>

BROCHURES & VIDEOS

-

Geotextile Reinforced Soil Bridges Brochure

8-page, full-colour brochure outlining GRS product, applications and specifications.

Download(9.17 MB)

-

Dur-A-Span GRS Bridge, North Saanich, BC

Take a video tour of this GRS Bridge that was a washout replacement from BC's “atmospheric river” weather event of 2021. Our patented GRS Bridges are fish- and wildlife-friendly, very resilient and don’t require concrete footings or pile foundations.

Play(1:39)

-

Geotextile Reinforced Soil (GRS) Bridge, Port Alberni, BC

Take a tour of the Trueman Creek GRS Bridge for BCMoTI — a washout replacement from an “atmospheric river” weather event. Our patented GRS technology uses steel anchor rods to connect the Super-Cor arch to the backfill/geotextile composite and transfer the loads into the surrounding GRS mass.

Play(1:37)

-

GRS Soil Bridge Technical Drawings

Download a PDF of our two largest pre-designed structures of Super•Cor Low Profile Arches; 20S Low Profile Arch and 28S Low Profile Arch.

Download(359.32 KB)

-

AIL Buried Metal Bridges & Tunnels Planning & Resource Guide

Discover how AIL's Buried Metal Bridges offer many advantages over concrete structures and bridges in this comprehensive guide with: benefits section; design ideas and sector/application galleries; complete product information and comparisons; and installation details.

Download(12.22 MB)